Newsroom

회사, 제품, 이벤트 및 업계 뉴스/보도자료

AGC Establishes Original MI Database and Analysis Tools

AGC (AGC Inc.: Headquarters, Tokyo; President, Yoshinori Hirai), a world-leading manufacturer of glass, chemicals, and high-tech materials, has developed its original Materials Informatics (MI) database, AGC R&D Data Input & Storage (ARDIS), and a dedicated Materials Informatics tool, AGC Materials Informatics Basis Analysis Tool (AMIBA). A pilot program for the tools, which began in 2020, is now complete, and full-scale use of the system will begin in AGC's R&D departments from June 2022.

In the development of materials, the conventional method to find new materials through repeated experiments is based on the knowledge and experience of researchers, which can take more than a decade. Materials Informatics, which uses computational and data sciences to significantly improve the efficiency of materials development, has been attracting attention in recent years. Yet until now, the storage format for experimental data has not been standardized, making it difficult to fully utilize MI.

AGC regards an integrated experimental data storage as an important platform for MI applications and has developed its own MI database system, ARDIS, which also functions as an electronic laboratory notebook for R&D tasks. The system accumulates data that can be used for MI by repeatedly recording daily experimental plans and results in ARDIS like a handwritten notebook. As data is shared among researchers and between organizations, using ARDIS improves the quality of R&D data and also allows for more efficient, data-driven R&D.

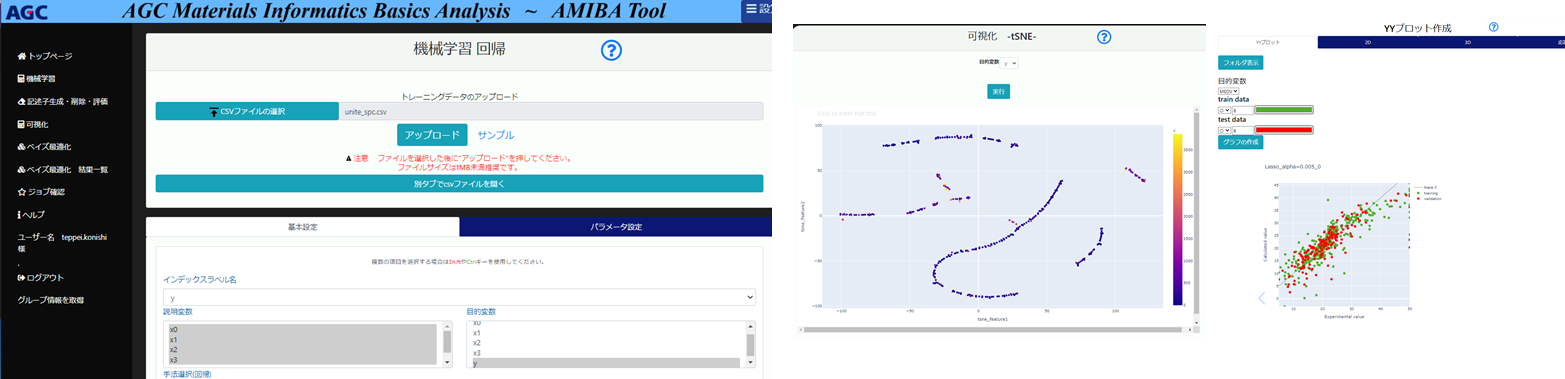

AGC has also developed its original MI tool called AMIBA to seamlessly utilize the experimental data accumulated in ARDIS. These systems allow researchers to thoroughly perform data input and analysis in a consistent manner, thereby advancing understanding of phenomena and estimating characteristics at all stages of development and accelerating R&D efficiency.

The pilot program for these tools, which began in 2020, demonstrated a variety of benefits, including the discovery of glass compositions that maximize strength of chemically strengthened glass used in smartphones and other electric devices as well as accelerating the design of high-quality coating materials to meet diverse needs for novel automotive glass. They are also used in the molecular design of polymers for fuel cells to explore advanced materials based on new perspectives according to the MI. In the future, AGC will further accelerate the development of new materials through MI by cultivating talent who can utilize data through initiatives such as in-house MI consulting.

In its medium-term management plan AGC plus-2023, the AGC Group has identified "strengthening competitiveness through accelerated DX" as one of the strategies to ensure the realization of its long-term management strategy, "Vision 2030". The AGC Group will utilize big data in all aspects of its business, including R&D, manufacturing, and sales, to further improve operational efficiency and provide new added value to its customers.

Reference

Relations between MI Database and Analysis Tools

ARDIS

This database system can store data from AGC's diverse research fields in a variety of data formats. Since processes, conditions, and measurements vary by field and theme in R&D, the system has functions that allow researchers to set up their own input interfaces and use them flexibly according to their needs. Data can be shared across research themes and organizations with appropriate access control. Accumulated data can be output in a format suitable for MI. The various keyword search functions make it possible to easily search and extract data accumulated to date, such as experimental conditions, compositions, and physical property values.

AMIBA

The in-house data analysis tool AMIBA is being introduced internally to enable researchers themselves to analyze data in their daily work and plan experiments efficiently. AMIBA makes is possible to examine experimental data, build machine learning models, and design experiments with simple operations.

Application of Computational Science and Technology

Thanks to its extensive in-house training programs, AGC's use of computational science and technology is also widespread. By utilizing in-house software that supports quantum calculations and molecular simulations, experimental researchers can proceed with materials development using MI while utilizing theoretical calculations. For example, it automates chemical reaction analysis using quantum calculations and is used to predict the synthesis of polymer materials.

MI Consulting

AGC, with its many product lines, has various research areas such as glass, chemistry, composite materials, electronic components, and bioscience, and the optimal MI approach for each theme is different. Therefore, MI consultants, together with simulation and data science experts, conduct MI consulting activities by department and theme, and facilitate the use of ARDIS and AMIBA. This clarifies the MI technology, talent resource development, and simulation tools required by each department and enables AGC to conduct MI dissemination activities appropriate to each technical domain.

DX-related Releases

October 9, 2019: AGC Establishes Original Data Scientist Training Program “Data Science Plus”

November 14, 2019: AGC Establishes Original "Causal Chain Analysis" Method for Defining Business Issues in the Era of Big Data

July 2, 2020: AGC and FRONTEO Co-develop "Takumi KIBIT," an AI-driven Q&A System

December 4, 2020: AGC Develops Integrated Operation Management System for Chemical Plants

May 25, 2021: Alteryx Data Analysis Platform to be Deployed to AGC's Chemical Plants

August 4, 2021: AGC and JAMSTEC Succeed in Developing World's First Highly Accurate Numerical Method to Predict Fracture Patterns in Chemically Strengthened Glass

Media inquiries

Chikako Ogawa, General Manager, Corporate Communications & Investor Relations Division

AGC Inc.

Contact: Kitano

TEL: +81-3-3218-5603

E-mail: info-pr@agc.com

*Personal information is handled in accordance with our Privacy Policy